|

| Hydraulic Hoses | All the hydraulic hoses are well arranged and safely stored in the hose rail on the headstock. The colour-coded and numbered hydraulic hoses guarantee a comfortable and error-free coupling to the tractor. To ensure that everything is at hand in the field, the Cayron is equipped with a storage rail for spare shear bolts and a spanner for the shear bolts and leg bolts. Particularly useful is the integrated scale on the spanner for measuring the working depth. |

|

| Robust turnover mechanism | The turnover mechanism is designed around a 130 mm diameter hollow shaft equipped with two equally large, high-quality, robust taper roller bearings. These are sealed against dirt ingress and can be lubricated to ensure a high longevity. Thanks to the hollow shaft, the hydraulic hoses can be neatly routed through the tube, ensuring a damage-free turn over procedure. The turnover mechanism is equipped with a one-piece sprung cross shaft which provides a very good damping function and so clearly reduces the strain on the lift linkage of the tractor. This is enabled by two pivoting bearings located on the right and left hand side of the cross shaft which safely absorb any shocks. 2 mounting positions of the lower link cross shaft allow the optimum matching to tyres and the lifting height of the tractor. Three positions for the top link attachment to the headstock ensure also the optimal lifting characteristics. If the top link is attached in one of the two slotted holes, then perfect adaptation to the ground and the maintenance of the preselected working depth is ensured. |

|

| Clever linkage system | The parallelogram linkage system is a central component on the plough and connects the plough beam with the turnover mechanism. The clever design of this linkage System is decisive for the exact and comfortable setting possibility, the low pulling power requirement and an always optimum ploughing performance. Easy setting of the plough The standard hydraulic front furrow adjustment (2) makes the beam setting simple and comfortable. Due to this design, the parallel shift of the plough requires very low power and thus is possible on the move without any problem. The pullline is factory set and usually does not require any readjustment. + Very useful when frequently changing tractors or in sloping terrain + Adjustable display of the front furrow width adjustment Optimum quality of work For the Cayron V, with hydraulic furrow width adjustment, the front furrow width is automatically and hydraulically matched when changing the furrow width. Here the plough is shifted in parallel via the linkage system. This is made possible by an oil exchange between the furrow width and front furrow cylinders. + Always an optimum ploughing performance with minimal wear and pulling power requirement 1 = Turnover cylinder 2 = Front furrow cylinder 3 = Furrow width cylinder |

|

| The beam swivels prior to the turning procedure | nother special benefit of the Cayron plough is that the beam swivels as standard prior to the turning procedure without any movement in the plough body bearings. This results in much more free space underneath the beam when turning and avoids wear. |

|

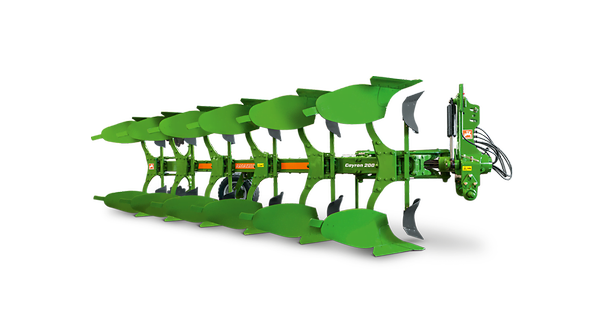

| Variable furrow width | All Cayron ploughs feature an adjustable furrow width. For the Cayron 200, this is achieved mechanically in 3 steps (40-45-50 cm per body) by swivelling the frame and then matching both the plough body and wheel position; the skimmers and the disc coulter are automatically matched. The Cayron V models feature a stepless, hydraulic furrow width adjustment from 30 to 55 cm per body. The large and clearly visible scale on the headstock shows the relevant adjusted furrow width. During the adjustment procedure, the front furrow width is automatically matched via the linkage system to ensure a continuous, optimum quality of work. |

|

| Combi depth wheel | The combi depth wheel can be used, both for depth guidance of the plough and for transport. The particularly easy conversion between work and transport position increases the comfort. The standardly provided damping cylinder does not need to be unhooked. The attachment of the wheel at the side of the beam eases ploughing operation at field sides and against other borders. Especially end user-friendly is the tool-less working depth adjustment against two stops. The combi depth wheel is equipped with a 340/55-16 tyre (∅ 770 x 340 mm width). |