Tyrok Semi-Mounted Reversible Plough

Overview

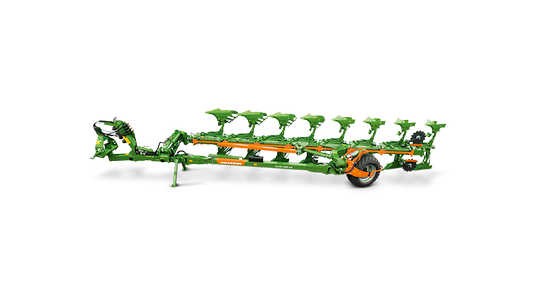

The new Tyrok plough enables AMAZONE to offer unique advantages for your farm. Maximum speed with minimum wear is possible thanks to the new SpeedBlade plough bodies. At the same time, the new over-dimensioned beam ensures a constant furrow depth over the full width. AMAZONE always offers the right solution for any farm with the new Tyrok, even those with the most diverse requirements.

Main Specifications

Features

| Optimised headstock design | The headstock of the Tyrok provides the perfect link up to the tractor with the minimum of wear. The headstock is rotatable by 180°, which enables the side pull to be reduced, thereby saving fuel. Maximum flexibility is also provided by two coupling options for the top link as well as the lower link cross shaft in Cat. 3, 4N and 4. The Tyrok can also be equipped with traction control as an option. Another hydraulic cylinder transfers weight onto the tractor’s rear axle thus increasing traction. This provides maximum pulling power whilst reducing fuel consumption. |

| SmartCenter for comfortable adjustment | The uncluttered hose rail enables optimum hose guidance to the tractor. So nothing stands in the way of quickly attaching the plough. In addition, all hydraulic functions can be controlled directly at the SmartCenter. This enables comfortable adjustmThe beam – pure strengthent of the plough right at the front and directly on the machine. |

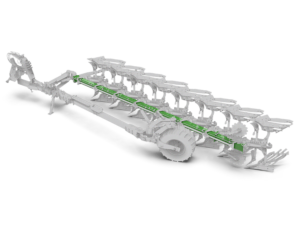

| The beam – pure strength The rectangular beam with the dimensions 200 x 150 x 10 mm minimises bending of the beam even under heavy load and hard soil conditions. The rigidity of the beam stops any bending, thereby ensuring the furrow depth remains constant across the entire furrow width. The rectangular shape also increases the load capacity of the beam. The beam height is 80 cm. 85 cm is also available as an option with shear bolt overload protection. | Extremely stable beam thanks to the over-dimensioned box section Comfortable and gentle turnover Safe and comfortable transport travel Constant furrow depth of all bodies thanks to the rigid beam High flexibility in the number of furrows Beam height 80 cm (85 cm as an option with shear bolt overload protection) |

| SmartTurn – Low-stress turnover in just 9 seconds! | Thanks to its twin-stage end-position damping, the plough’s turning process is slowed down shortly before reaching the end of travel. This results in a damping effect which reduces stress on the materials when the cylinder is retracted. There is no need to make any compromises here as the low-stress turnover process is completed within only 9 seconds. |

| Box section beams made of high-grade steel for a long service life | All the beams on AMAZONE ploughs are produced from a special high-tensile steel. The over-sized wall thickness means that, not only is the whole beam robust, but also all the bolt fixings are extremely strong with this heavy wall thickness also preventing any hole elongation or deformation of the box section around the bolt fixings. A further feature of the ploughs is the design of the plough beam without any weld seams. |

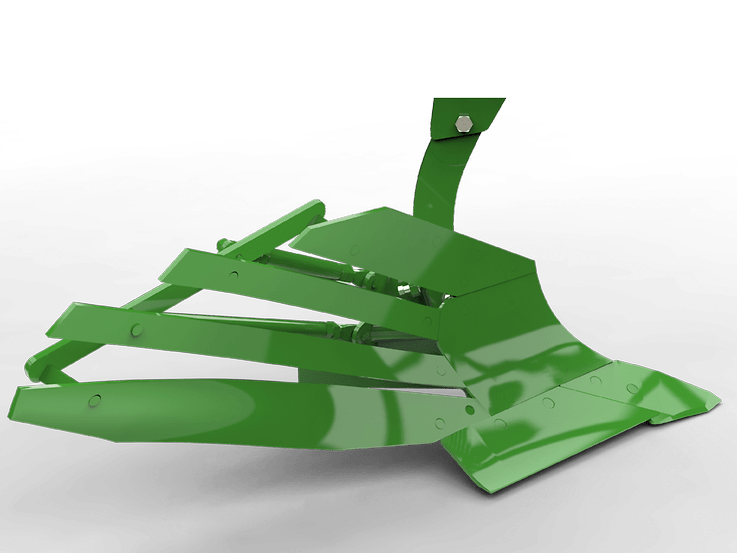

| SpeedBlade Maximum speed – Minimum wear | The new SpeedBlade plough bodies with their patented extra-large front shin on the mouldboard and the ©plus hardening process ensure significantly less wear at high forward speeds. As ploughing speeds increase, the wear point shifts further to the rear. Wear on conventional plough bodies begins directly on the wing at higher speeds as a result of the small front shin of the mouldboard. Only the front shin of the mouldboard has to be replaced thanks to the patented enlarged front shin of the mouldboard. This avoids the troublesome and expensive replacement of the entire wing. |

| Hydraulic overload protection | The hydraulic overload protection is basically a hydraulic cylinder with a directly connected, nitrogen-filled hydraulic accumulator on each pair of plough bodies. When triggered, the plough body pushes a piston into the accumulator via the hydraulic cylinder. The gas is compressed and automatically returns the body to its initial position after passing the obstacle. A choice can be made between the standard hydraulic protection with decentralised adjustment or the optional protection with central adjustment for convenient and quick adjustment of the release pressure of all bodies |

| Tyrok V – Comfortable hydraulic operation | The furrow width can be smoothly and hydraulically adjusted from the tractor in Tyrok V ploughs. A very clearly visible display, consisting of a scale and indicator, keeps the driver informed about the furrow width setting. The integrated kinematics of the Tyrok V also automatically set the pull point, the front furrow width, all the soil engaging tools and the support wheel. |

| Tyrok – mechanically simple | The standard furrow width adjustment can be altered in 4 steps by manually pivoting the leg fixing consoles. The implement can therefore easily be adapted to different conditions (soil conditions, tractor, etc.). When the furrow width is adjusted, all the soil-engaging metal and support wheels are also automatically adjusted. No additional correction is necessary. |

| Front furrow width – Always the right setting AutoAdapt – Automatic adjustment of the front furrow when changing the furrow width | The front furrow width is automatically adjusted when changing the furrow width to enable a perfect matching up even under changing conditions. The standard hydraulic adjustment of the front furrow guarantees high quality operation under all conditions. At the same time, it is possible to react to changing conditions quickly and comfortably. The swing arm is controlled directly by the cylinder during the process. As a result, inside wheel track dimensions from 1.2 m to 1.6 m are possible. |

| The support wheel Exact depth control combined with perfect boundary ploughing | The various tyre sizes mean that the support wheel can be optimally adapted to the practical requirements. |

| Exact depth control | A choice of large-dimensioned support wheels provide optimum ground drive and exact depth control, even under the most arduous of conditions. The depth is easily adjusted by means of the support wheel via a hydraulic cylinder or clips on the piston rod without using tools. The scraper reliably cleans the wheel. The standard hydro-pneumatic suspension of the support wheel provides maximum safety and the highest comfort on the road. |

| Do | |

| NOT DELETE | |

| THIS TABLE | |

| IT CREATES CSS THAT IS USED | |

| in the ACF Repeater | |

| JET Engine fields | |

| for the engine specs - Ken | |

| DEF (AdBlue) Capacity |