Catros-2TX trailed compact disc harrow

Overview

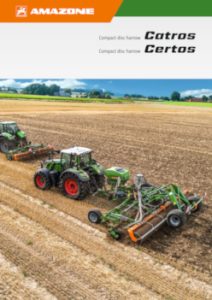

The Catros-2TX is ideally suited for shallow and intensively mixing soil tillage. The centre running gear provides the machine with a high manoeuvrability and allows the safe and quick road transport irrespective of working widths of 7 m to 9 m. The exceptional running gear and easy pull guarantee the highest operational comfort and utmost efficiency.

Main Specifications

Catros+/CatrosXL 7003-2TX, 7.0 m working width

Catros+/CatrosXL 8003-2TX, 8.0 m working width

Catros+ 9003-2TX, 9.0 m working width

Features

| Outstandingly low fuel consumption | With the Catros compact disc harrow, operational speeds of 12 km/h to 18 km/h are achieved problem-free, enabling outstandingly high work rates and reducing the operational time to a minimum. Important, however, for economic success, are both the fuel, and the wear and tear costs. In order to determine reliable figures for these costs AMAZONE has carried out trials in collaboration with the DLG test centre in Gross-Umstadt. In all the tests, the Catros compact disc harrows proved to be extremely fuel efficient. So when stubble cultivating at a medium working depth of about 6 cm – depending on soil type and ground topography – an approximate fuel consumption of only 4 l/ha was measured. Similarly favourable were the consumption figures during seedbed preparation. |

| Catros+/ CatrosXL discs – for an intensive mixing | The serrated Catros+ discs with a diameter of 510 mm and the CatrosXL discs with a diameter of 610 mm are characterised by their more aggressive operation and a more reliable penetration even under difficult conditions. The optimum operational range of these discs is for stubble tillage, seedbed preparation and also the incorporation of cover crop residues. |

| No lubrication ever again – thanks to the maintenance-free disc bearings | With no need to lubricate the disc bearings, this results in a significantly reduced overall maintenance time. Face seals have been used for decades in road construction equipment where the rollers on the running gear of caterpillar-tracked vehicles have to be effectively sealed and continue to work absolutely reliably under the toughest of operational conditions. |

| Oversized disc bearings | Due to the robust design, maintenance-work and running costs are again kept to a minimum and long life times are guaranteed even under the most arduous operational conditions. |

| ContourFrame – For Catros-2TX | The Catros-2TX trailed compact disc harrows are divided into distinct sections, so that each of these sections ensures a consistent working depth and also, when working on hills or in hollows, a maintained depth is ensured. The Catros-2TX-models each feature 2 outer sections and one centre section. The principle at the rear of the machine is that the depth guidance of the sections is carried out via the following roller whereas, at the front, the 2 outer sections on the Catros-2TX are supported via support wheels and the centre section via the drawbar. The short distance between support wheels and the roller ensures the superb contour following over hills and through hollows. |

| Smooth, even ride | During operation the wings are pre-pressurised via hydraulic accumulators. The hydraulic pre-pressurising allows individual ground contour following on any of the sections, both upwards and also downwards. In this way, the machine Frame optimally follows the ground contours over the entire width and provides an even work profile over the entire working width. Thanks to the individual contour following, a smooth ride is possible even under difficult operational conditions and thus an even quality of work is guaranteed. |

| Comfort comes up trumps | Catros-2TX machines are characterised by their smooth travel because the weight of the running gear evenly rests on the disc section and the following rollers. In addition the weight of the running gear increases the even penetration of the machine into the soil. Thanks to the centre running gear, Catros-2TX machines are very manoeuvrable. An additional benefit is their operational flexibility as numerous possible following rollers are available. |

| Optimum reconsolidation | Depending on the kind of soil, the range of following rollers are designed to provide intensive crumbling and reconsolidation. Changing rollers just requires a pair of brackets to be loosened. The large distance between discs and following roller ensures that the soil settles again and can be perfectly reconsolidated by the following roller. |

| The perfect supplement for seedbed preparation | For seedbed preparation for maize or sugar beet, the AMAZONE compact disc harrows can be equipped with a variety of rollers in addition to a following harrow. The following harrow creates a very fine-crumbled soil surface structure and thus the perfect germination conditions for the following crops. An additional advantage when using the harrow is the optimised straw distribution. |

| Cover crop sowing and soil tillage in one operational pass | AMAZONE offers the GreenDrill cover crop seeder box so that cover crops can be applied directly or together with the soil tillage operation. It can be combined with the Catros+ and CatrosXL disc harrows. The seed is distributed evenly by the spreader plates The GreenDrill seed hopper holds 200 l or alternatively 500 l and is easily accessed via the loading steps provided. In the metering system below the seed hopper, a seed shaft is fitted with normal or fine seed wheels depending on the seed type and desired application rate. The drive to the seed shaft is electric and that of the blower fan either electric or hydraulic. |

| For the most arduous of applications | In order to increase the penetration into the soil on dry, hard soils, additional weights slices are available as a special option. One weight set consists of four 25 kg elements. The maximum additional weight for rigid machines is 200 kg and for foldable, 3-point linkage models, and on the Catros-2TS models, (in 4 m to 6 m working width) the extra weight is limited to 300 kg |

| Transport box | The optional transport box, which can be fitted to the drawbar, offers additional and valuable storage space for the Catros-2TX. |

| Crushboard – for perfect seedbed preparation | For even better levelling and crumbling, a Crushboard is available for Catros-2TX . With this special option, after ploughing, for instance, coarse surface clods be crushed and the seedbed optimally prepared. The depth setting is carried out steplessly mechanically or is, as an option, also available with a comfortable hydraulic depth setting which allows the very precise and infinitely variable adjustment from the tractor seat. |

| Central lubrication | Another special option that AMAZONE offers is central lubrication for the Catros-2TX. For the simplification of the lubrication process, a manual central lubrication system is available as an entry-level solution. Here one grease nipple serves as the supply for all greasing points on the machine. Hereby, sub-distributors guarantee supply to the lubrication points. The benefit of this system is that the grease gun has to be used just at the one point on the implement and no climbing on to the implement, which is heavily polluted with slurry and soil, is necessary. For maximum comfort an electric central lubrication system is available. It provides the automatic supply to all lubrication points on the Catros+ with pro-Pack. In this way the maintenance can be significantly reduced and the reliability further improved. The electric central lubrication system is the comfortable solution for professional farms needing high work rates and with tight maintenance timeframes because expensive downtime can be saved. |

| Do | |

| NOT DELETE | |

| THIS TABLE | |

| IT CREATES CSS THAT IS USED | |

| in the ACF Repeater | |

| JET Engine fields | |

| for the engine specs - Ken | |

| DEF (AdBlue) Capacity |