Cenius-2TX trailed cultivator

Overview

The 4-stagger Cenius-2TX trailed cultivator, in working widths from 4 m to 8 m, can be operated from shallow stubble tillage right down to top soil deep loosening. Due to the wide-ranging share and roller programme, the implement can be matched to virtually any field conditions. The integrated centre running gear provides the machine not only a high maneuverability on the road but allows, if necessary, operation without a following roller.

Main Specifications

Features

| Top benefits of the Cenius cultivators | Wide range of C-Mix shares – a suitable share for any working depth and any application Easy and quick share change thanks to the C-Mix Clip quick change system Consistent depth control even under the most arduous of conditions, made possible by the high release forces of the overload protection system on the C-Mix Special and C-Mix Super tines A wide range of levelling tools ensure the optimum levelling under all conditions Particularly easy to pull and fuel saving yet with a very good loosening and mixing effect thanks to the optimum tine arrangement and tine angling Following rollers for any location ensure an optimum reconsolidation |

| More with less – Cenius | More strength More operating possibilities More comfort and convenience Less blockages Less fuel used Less wearing costs |

| C-Mix Special tines with shear bolt overload safety device | The C-Mix Special tine with its shear bolt overload safety device is the ideal and cost effective alternative for light and medium light soils without stones. Thanks to the low weight of the C-Mix tine, these are especially suitable for operation behind tractors with less lift capacity. |

| C-Mix Super tines with 600 kg pressure spring overload safety device | Together with the overload safety device, the C-Mix Super tine provides the perfect operational performance even when top soil deep loosening. The release force of the pressure spring overload safety device of the C-Mix Super tine exceeds 600 kg and features a lift potential of 30 cm. If this large lifting space of 30 cm is not sufficient, the C-Mix Super tine offers additional safety via a shear bolt. In this way an efficient and constant operation is possible even under the most of arduous of conditions. |

| Hardwearing HD version | The 350 mm wing share, the 80 mm share and the 40 mm share are also available as a hardwearing HD version especially for areas that have high usage capacity. During the entire lifespan, the length of the share is maintained. So, no readjustment of the depth is necessary. Depending on application and soil conditions, the service life is up to five times longer than with the standard points. |

| Reliable disc bearings | The individual concave discs are mounted via rubber spring elements and thus feature a maintenance-free overload safety device. The bearings of the discs are, of course, maintenance-free. |

| Levelling and crumbling | Top-class levelling of the worked soil horizon is the basic requirement for an even reconsolidation. This is why, mounted behind the tine rows, an additional levelling system is attached. Available here is a choice of spring steel closers or smooth and serrated levelling discs. To ensure a clean matching to the next bout, the side discs and outer spring steel closers are adjustable in their height and angle. |

| Loosening and mixing | The 3-stagger and 4-stagger layout of the tines in the main frame ensure an intensive and optimum incorporation of straw residues in the top soil. Thanks to the narrow row spacings of less than 30 cm, dry, hard topsoil is worked across the full area. At the same time, the spacious tine to tine spacings and the huge frame height of 80 cm provide a high material passage and ensure the highest operational reliability. |

| Integrated running gear in a class of its own | |

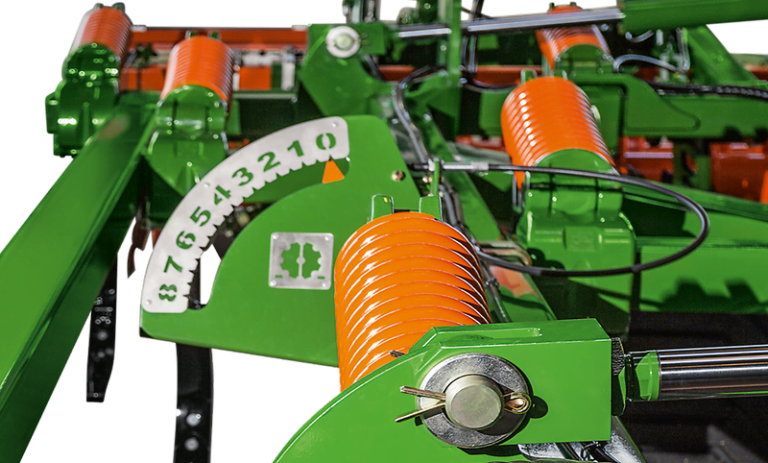

| Centralised and simple depth adjustment | At the front of the machine, support wheels carry out the depth guidance. At the rear of the machine the depth rollers take over this task. |

| Fast on the road | The smaller trailed Cenius 4003-2TX and 5003-2TX are equipped as standard with the 400/60-22.5 tyres, whereas, on the wider 6003-2TX to 8003-2TX, the oversized 550/45- 22.5 tyres are fitted as standard. As an option, these are also available for the Cenius 4003-2TX and Cenius 5003-2TX. For the wider models, 700/40-22.5 tyres are available as well. When equipped with air braking, high speed transport of up to 40 km/h is permitted. |

| High output | Working widths of up to 8 m in combination with the optional traction assistance provide a high work rate. Thanks to its centre running gear, the Cenius-2TX is especially manoeuvrable on the road and in the field. |

| Optimum reconsolidation | Depending on the kind of soil, the range of following rollers are designed to provide intensive crumbling and reconsolidation. Changing rollers just requires a pair of brackets to be loosened. The large distance between discs and following roller ensures that the soil settles again and can be perfectly reconsolidated by the following roller. |

| Do | |

| NOT DELETE | |

| THIS TABLE | |

| IT CREATES CSS THAT IS USED | |

| in the ACF Repeater | |

| JET Engine fields | |

| for the engine specs - Ken | |

| DEF (AdBlue) Capacity |